Uhlobo lwe-SH lwenqanaba elinye impompo yokuhluza kabini

Ingcaciso yeMveliso

I-S, iimpompo zohlobo lwe-SH zinenqanaba elinye, iimpompo ze-centrifugal zokufunxa kabini ezihlulwe kwi-casing yepompo, ezisetyenziselwa ukupompa amanzi acocekileyo kunye nolwelo oluneempawu ezibonakalayo kunye neekhemikhali ezifana namanzi.

Olu hlobo lwempompo lunentloko yeemitha ezili-9 ukuya kwi-140 yeemitha, isantya sokuhamba kwe-126m³/h ukuya kwi-12500m³/h, kwaye ubushushu obuphezulu bolwelo akufunekanga budlule kwi-80°C.Ilungele iifektri, imigodi, unikezelo lwamanzi ezidolophini, izikhululo zombane, iiprojekthi ezinkulu zokonga amanzi, ukunkcenkceshela komhlaba weefama kunye nokukhupha amanzi.njl., iimpompo ze-48SH-22 ezinkulu zingasetyenziswa njengeempompo ezijikelezayo kwizikhululo zamandla ezishushu.

Intsingiselo yemodeli yempompo: njenge-10SH-13A

I-10-I-diameter ye-suction port yahlulwe ngama-25 (oko kukuthi, ububanzi bezibuko lokufunxa lempompo yi-250mm)

S, SH ukufunxa kabini kwinqanaba elinye lempompo yamanzi esentini

I-13-Isantya esithile sahlulwe nge-10 (oko kukuthi, isantya esithile sempompo yi-130)

A kuthetha ukuba impompo ithathelwe indawo kunye ne-impellers yee-diameters zangaphandle ezahlukeneyo

Iiparamitha zokuSebenza

Uluhlu lweParameter kunye nentsingiselo yemodeli yohlobo lwe-SH lwenqanaba elinye lokufunxa kabini ukuqukuqela okukhulu okuvulekileyo-uhlobo lwempompo ye-centrifugal:

Ukuhamba (Q): 110—12020m3/h

Intloko (H): 8—140m

Umzekelo: 6-SH-6-A

I-6- I-diameter ye-inlet yempompo yi-intshi ezi-6

SH-Horizontal impompo yokwahlula-kwinqanaba elinye kabini

I-6 - 1/10 yesantya esithile sempompo ijikelezwe

I-Impeller ikhowudi yokusika i-diameter yangaphandle

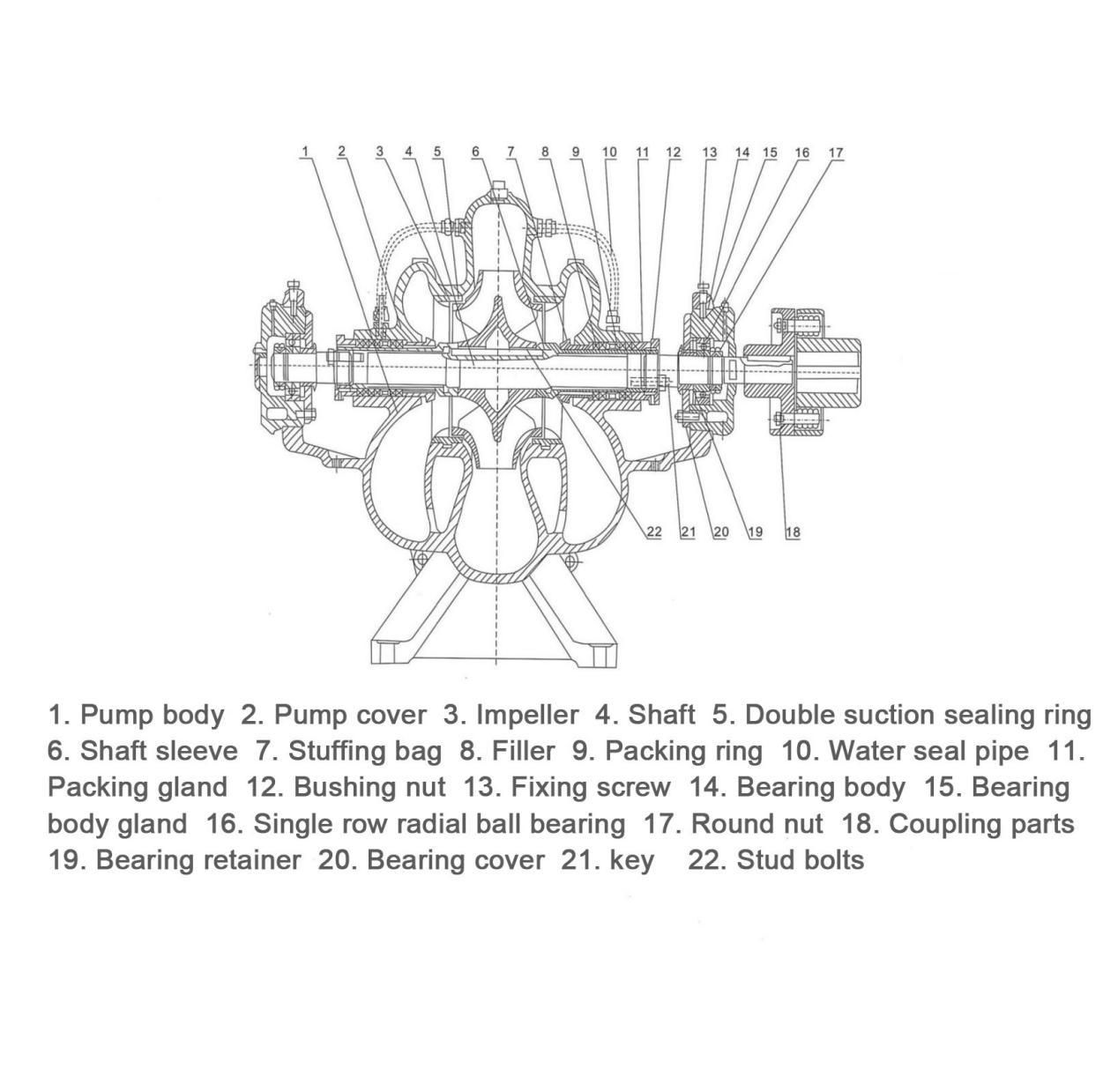

INdibano, ukuchithwa kunye nokufakelwa kwempompo yokwahlukana kohlobo lwe-SH

Iimpawu zesakhiwo sohlobo lwe-SH lwenqanaba elinye lokufunxa kabini ukuqukuqela okukhulu kwempompo esembindini:

Ubume beCompact: imbonakalo entle, uzinzo oluhle kunye nokufakwa lula.

Ukusebenza okungenamagingxigingxi: I-impeller eyilwe ngokugqibeleleyo yokufunxa kabini inciphisa amandla e-axial ukuya kubuncinci, kwaye ineprofayili ye-blade esebenza kakuhle kakhulu ye-hydraulic.ukusebenza kakuhle.

Itywina le-Shaft: khetha i-BURGANN yesitywina ngoomatshini okanye isitywina sokupakisha.Inokuqinisekisa iiyure ezingama-8000 zokusebenza ngaphandle kokuvuza.

Iibheringi: Iibheringi ze-SKF kunye ne-NSK zikhethiweyo ukuqinisekisa ukusebenza kakuhle, ingxolo ephantsi kunye nobomi benkonzo ende.

Ifom yokufakela: Akukho luhlengahlengiso olufunekayo ngexesha lokudibanisa, kwaye lunokusetyenziswa ngokwemiqathango yesayithi.Ufakelo olukhethekileyo okanye oluthe tye.

Ukudityaniswa kunye nokwahlukaniswa kohlobo lwe-SH lwenqanaba elinye lokufunxa ipompo enkulu yokwahlulahlula okuphakathi kwempompo:

1. Hlanganisa iinxalenye ze-rotor: faka i-impeller, i-shaft sleeve, i-nati ye-shaft sleeve, i-sleeve yokupakisha, i-ring yokupakisha, i-gland yokupakisha, i-ring yokugcina amanzi kunye neendawo zokuthwala kwi-shaft shaft ngokutshintshana, kwaye ubeke umsesane wokutywina kabini, kwaye emva koko ufake i-Coupling.

2. Faka iinxalenye ze-rotor kumzimba wempompo, ulungelelanise indawo ye-axial ye-impeller phakathi kweendandatho zokutywinwa kabini zokufunxa kumacala omabini ukuyilungisa, kwaye ugxininise i-gland ye-bearing body kunye nezikrini zokulungisa.

3. Faka ukupakisha, ubeke iphedi yephepha eliphakathi, uvale isigqubuthelo sempompo kwaye uqinise iphini lomsila we-screw, uze uqinise i-nut yesigqubuthelo sempompo, kwaye ekugqibeleni ufake i-grave material gland.Kodwa musa ukucinezela ukupakisha kakhulu, kuya kubangela ukuba i-bushing ishushu kwaye idle amandla amaninzi, kwaye ungayicinezeli ngokukhululekileyo, iya kubangela ukuvuza okukhulu kolwelo kunye nokunciphisa ukusebenza kwempompo.

Emva kokuba indibano igqityiwe, vula i-shaft yempompo ngesandla, akukho nto yokuxubha, ukujikeleza kuhambelana ngokufanelekileyo kwaye kunye, kwaye ukuchithwa kungenziwa ngokulandelelana kwendibano engentla.

Ujongo lokuFakelo:

1. Khangela ukuba impompo yamanzi kunye nemoto akufanele yonakaliswe.

2. Umphakamo wofakelo wempompo yamanzi, kunye nelahleko yokwenziwa koxinzelelo lomoya wombhobho wokufunxa, kunye nesantya sawo samandla, abuyi kuba mkhulu kunexabiso lomphakamo oluvumelekileyo lokufunxa elichazwe yisampuli.Ubungakanani obusisiseko kufuneka buhambelane nobukhulu bofakelo lweyunithi yempompo.

3. Ulandelelwano lofakelo:

① Beka impompo yamanzi kwisiseko sekhonkrithi engcwatywe ngeebholiti ze-ankile, lungisa inqanaba ngokuhlengahlengisa isithuba esimise okweweji phakathi, kwaye uqinise ngokufanelekileyo iibholithi ze-ankile ukunqanda ukunyakaza.

② Galela ikhonkrithi emva kwesiseko kunye nonyawo lokumpompa.

③ Emva kokuba ikhonkrithi yomile kwaye yomelele, qinisa iibholithi ze-ankile kwaye ujonge kwakhona umgangatho wempompo yamanzi.

④ Lungisa ubunzulu beshafti yemoto kunye neshafu yempompo yamanzi.Yenza i-shafts ezimbini kumgca ochanekileyo, ukunyamezela kwe-coaxiality kwisangqa sangaphandle se-shafts ezimbini ngu-0.1mm, kunye nokunyamezela kokungalingani kwe-gap yobuso besiphelo ecaleni komjikelezo ngu-0.3mm (jonga emva kokudibanisa amanzi. imibhobho yokungena neyokuphuma kunye nokuqhutywa kovavanyo) , kusafuneka ihlangabezane nezi mfuno zingasentla).

⑤ Emva kokujonga ukuba ukulawulwa kwemoto kuhambelana nokulawulwa kompompo wamanzi, faka ukudibanisa kunye nezikhonkwane zokudibanisa.

4. Imibhobho yokungena kwamanzi kunye nokuphuma kwamanzi kufuneka ixhaswe ngezibiyeli ezongezelelweyo, kwaye akufanele zixhaswe ngumzimba wempompo.

5. Itheyibhile yokudityaniswa kwempompo kunye nombhobho kufuneka iqinisekise ukuxinana komoya okulungileyo, ngakumbi umbhobho wokungena kwamanzi, ekufuneka ungangeni moya ngokungqongqo, kwaye akufuneki kubekho nto inokwenzeka yokubambisa umoya kwisixhobo.

6. Ukuba impompo yamanzi ifakwe ngaphezu komgangatho wamanzi ongenayo, ivalve ephantsi ingafakwa ngokubanzi ukuze kuqaliswe impompo.Indlela yokuguqula ivacuum nayo ingasetyenziswa.

7. Emva kwempompo yamanzi kunye nombhobho wokuphuma kwamanzi, ngokuqhelekileyo kuyimfuneko ukufaka ivalve yesango kunye nevalve yokukhangela (i-lift ingaphantsi kweemitha ezingama-20), kwaye ivalve yokukhangela ifakwe emva kwevalve yesango.Indlela yokufakela echazwe ngasentla ibhekisela kwiyunithi yempompo ngaphandle kwesiseko esiqhelekileyo.

Faka ipompo kunye nesiseko esiqhelekileyo, kwaye ulungelelanise inqanaba leyunithi ngokulungelelanisa i-shim ene-wedge phakathi kwesiseko kunye nesiseko sekhonkrithi.Emva koko uthele ikhonkrithi phakathi.Imigaqo yokufakela kunye neemfuno ziyafana nezo zeeyunithi ngaphandle kwesiseko esiqhelekileyo.

Impompo yokuqalisa, yima kwaye ubaleke:

1. Qala kwaye umise:

Ngaphambi kokuba uqale, vula i-rotor yempompo, kufuneka ibe lula kwaye ilingane.

②Vala ivalve yesango lokuphuma, kwaye utofe kwimpompo (ukuba akukho valve esezantsi, sebenzisa impompo yokufunxa ukukhupha amanzi) ukuqinisekisa ukuba impompo izele ngamanzi kwaye akukho zipokotho zomoya.

③ Ukuba impompo ixhotyiswe ngegeyiji yokufunxa okanye igeyiji yoxinzelelo.Cima isiseko esijikelezayo esiqhagamshelwe kwimpompo kwaye uqalise i-motor.Emva kokuba isantya siqhelekile, yivule;uze uvule ngokuthe ngcembe ivalve yesango lokuphuma.Ukuba ukuhamba kukhulu kakhulu, unokuvala ngokufanelekileyo ivalve yesango elincinci.Lungisa;ngaphandle koko, izinga lokuhamba lincinci kakhulu.Vula ivalve yesango.

④ Qinisa i-nut yoxinzelelo kwidlala lokupakisha ngokulinganayo ukwenza ulwelo luvuze ngamathontsi.Ngexesha elifanayo, qaphela ukunyuka kweqondo lokushisa kwindawo yokupakisha.

⑤ Xa umisa ukusebenza kwempompo yamanzi, vala kuqala inkuku yegeyiji yokufunxa kunye negeyiji yoxinzelelo kunye nevalve yesango kumbhobho okhupha amanzi.Emva koko cima amandla enjini.Njenge

Xa ubushushu bemekobume buphantsi, iplagi ye-screw yesikwele kwindawo esezantsi yempompo yomzimba kufuneka ivulwe, kwaye amanzi kufuneka asuswe ukuphepha ukukhenkceza.⑥Xa ingasetyenziswa ixesha elide, impompo yamanzi kufuneka ichithwe kwaye amanzi kwamanye amalungu kufuneka ome.Faka ioli ye-anti-rust kwindawo yokucubungula kwaye uyigcine kakuhle.

Umsebenzi:

① Ubushushu obuphezulu bempompo yamanzi akufunekanga budlule kuma-75°C.

② Ubungakanani bebhotela esekelwe kwi-calcium esetyenziselwa ukuthambisa i-bearing kufuneka ibe yi-1/3 ukuya kwi-1/2 yesithuba somzimba wokuthwala.

③ Xa ukupakisha kugugile, idlala lokupakisha lingacinezelwa ngokufanelekileyo.Ukuba inxibe kakhulu, kufuneka itshintshwe.

④ Jonga iindawo zeshaft rhoqo.Nika ingqalelo ukunyuka kweqondo lokushisa lokuthwala i-motor.

⑤ Ngexesha lokusebenza, ukuba ufumana ukugquma okanye ezinye izandi ezingaqhelekanga, kufuneka usimise isithuthi ngoko nangoko.Khangela unobangela uze uwuphelise.

⑥ Musa ukunyusa isantya sempompo yamanzi ngaphandle kwesizathu.Nangona kunjalo, inokusetyenziswa ngesantya esisezantsi.Ngokomzekelo, isantya esilinganisiweyo solu hlobo lwempompo ngu-n, ukuhamba ngu-Q, ukuphakanyiswa ngu-H, amandla e-shaft ngu-N, kwaye isantya sincitshiswe kwi-n1.Kwi-Q1, i-H1 kunye ne-N1.Ubudlelwane babo bobabini.Inokuguqulwa ngale fomula ilandelayo:

Q1=(n1/n)Q H1=(n1/n)²H N1=(n1/n)³N